General information

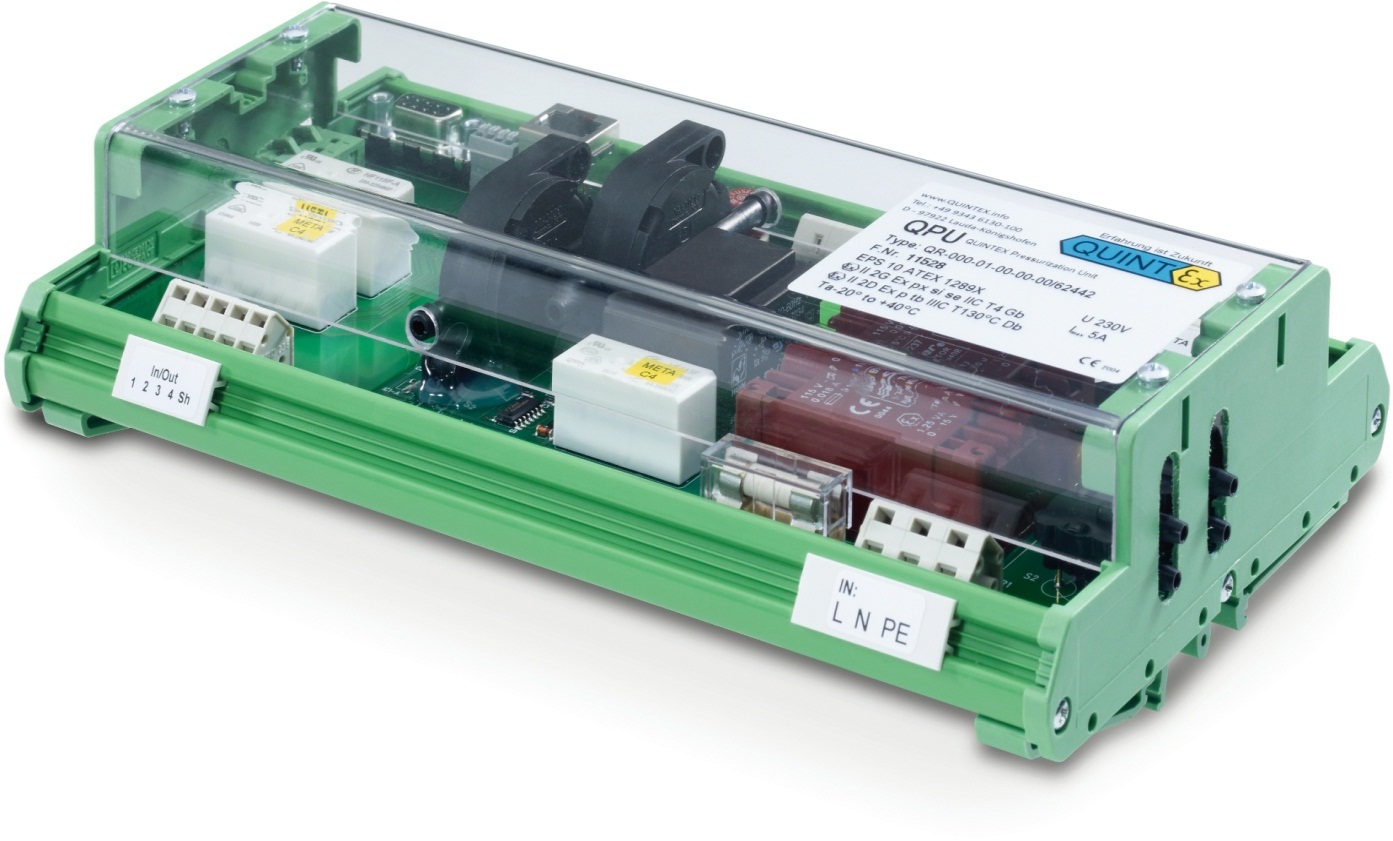

The explosion protection at the "overpressure system 2.0" is realized by operating a non-explosion-protected equipment in a protected enclosure. This housing is protected by a durable pressure with air or an inert gas prior to penetrate the enclosure or cabinet by possibly explosive atmosphere. In the new approach developed by Quintex, it is not flushed, but released for operation by a gas detector of the cabinet. You can use your favorite gas detector for this application...

no additional maintenance work for the gas detectors. This ensures that no explosive gas/air

mixture is present. This saves time, programming knownledge and expensive pressurized air and accelerate the operation of the non ex devices.

Coverage of air leakage

In operation and after releasing, a positive overpressure in the mbar range is maintained within the cabinet. On the input side of pressurized air (gas) you can uses solenoid valves (open / closed) as well as proportional valves to cover the air leakage of the cabinet.With our control unit for digital valves, the pressure air is supplied through a hysteresis in the range of 6mbar(hPa) (valve open) and 10mbar(hPa) (valve closed). This can be omitted expensive proportional valves

and

simultaneously

thus leakage changes (e.g: Increasing the leakage losses due to aging processes), are automatically compensated.

Home

Home

We

We

Products

Products

Calculators

Calculators

Contact

Contact